Die Casting

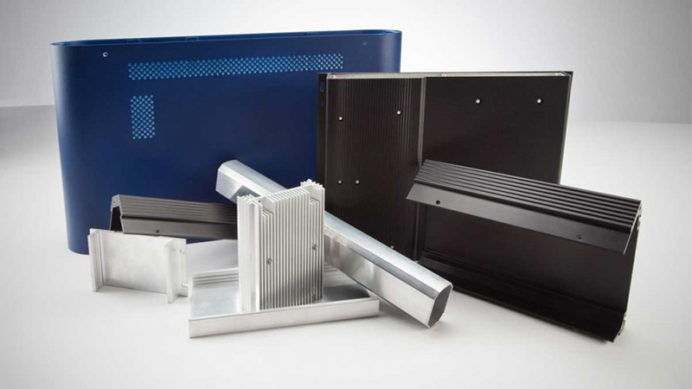

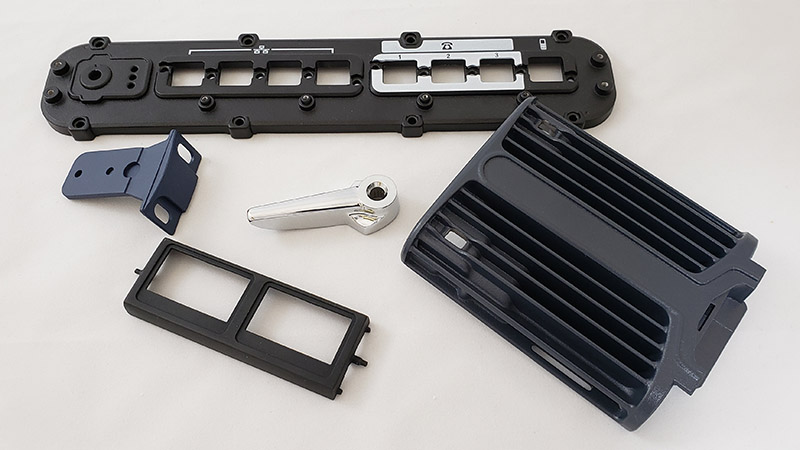

Die casting is a process of forcing molten metal under high pressure into a mold cavity. The mold cavity is the shape of the desired part. Most die castings are aluminum, magnesium, or zinc. Depending on the type of metal being cast, a hot or cold chamber machine is used.

The metal dies can be expensive, which tends to limit the process to higher volume production. Die casting is well suited for small to medium size parts. Die castings are characterized by a very good surface finish and dimensional consistency.

Tanfel offers clients a variety of finishing process options for casted parts.

Advantages of Die Casting

- Good dimensional accuracy

- Good surface finish

- Die casting can achieve thinner walls than investment casting

- Efficient use of raw material and fast production rate

Die Cast Metals: Aluminum, Zinc, and Magnesium

Aluminum

-

- 130 ton – 1250 ton

- 1 oz. to 15 lbs.

Zinc

-

- 12 ton – 200 ton

- 1 oz. to 5 lbs.

- Thin wall casting as low as 0.014in

Magnesium

-

- 160 ton to 800 ton

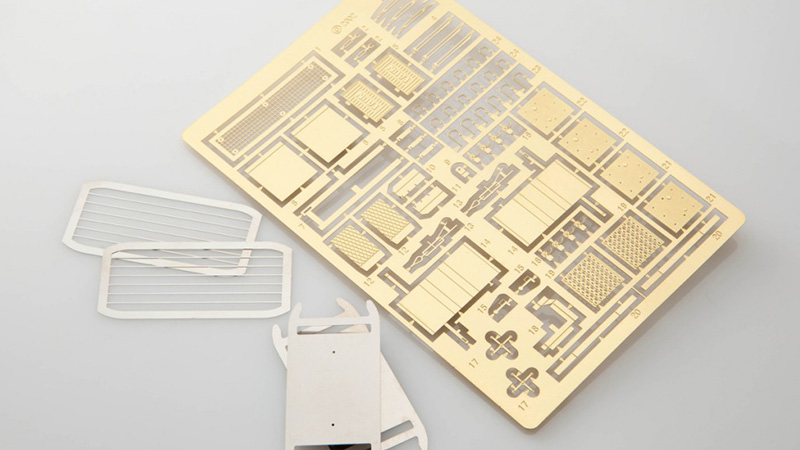

- Secondary Operations: Trim press, drill and tap, CNC, polishing, buffing, vibratory finish, shot blasting

- Finish: Chrome-free passivation, Teflon coating, Ceramic coating, polishing, wet paint, powder coating, Silkscreen, Pad printing, Sand blasting

Die Casting Alloy Selection

Die-casting alloy selection is based on the application and functionality of the product or part in question. Different metals have their own characteristics.

Basic guidelines for Aluminum, Zinc and Magnesium alloys:

Aluminum Alloys:

- Relatively lightweight (270% lighter than zinc)

- High resistance to corrosion

- Good mechanical properties

- Good dimensional stability

Zinc Alloys:

- Considered as the easiest to cast

- Longer tool life due to lower temperatures and pressures

- Ability to be produced in thin wall thicknesses and tighter tolerances

- Good for plating and coating

Magnesium Alloys:

- Lightest weight among commonly used structural metal (50%) lighter than aluminum

- High strength to weight ratio

- Excellent damping ability

- EMI shielding ability

Contact us or request a quote today to learn more about our die casting services.