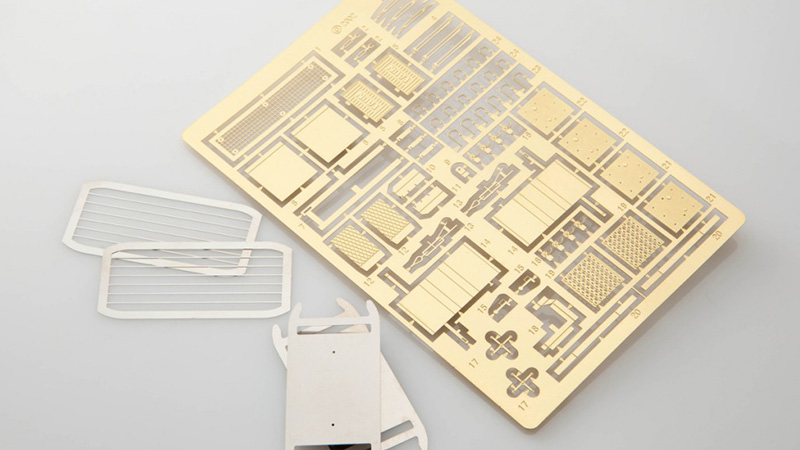

Photo Etching – Chemical Etching

Chemical milling corrosively machines away selected sheet metal material to produce a complex part with fine detail. Photo etching can be used as an alternative to stamping, punching, water jet cutting or EDM for very thin gauge parts.

Typical material thickness-under 0.05” (1.3mm).

This process is also called Photo chemical machining – PCM, Chemical etching, Chemical milling.

- Stainless Steel , Copper , Brass , Aluminum

- Maximum size sheet: 11.8 in x 23 in

- Pressing plus etching available

Guidelines for the design of etched components

General Tolerance

| Thickness | Tolerance |

|---|---|

| ≤ 0.002 in | +/- 0.0002 – 0.0004 in |

| 0.002 – 0.005 in | +/- 0.0004 – 0.00078 in |

| 0.005 – 0.008 in | +/- 0.0012 – 0.0016 in |

| ≥ 0.01 in | +/- 0.002 in |

Minimum Hole Size

| Thickness | Minimum Hole Diameter |

|---|---|

| 0.002 – 0.004 in | 1.2x material thickness (in) |

| 0.006 – 0.0078 in | 1.1x material thickness (in) |

| ≥ 0.01 mm | 1.0x material thickness (in) |

Minimum Line Width

| Thickness | Minimum Line Width |

|---|---|

| 0.004 in | 0.0025 in |

| 0.006 – 0.0078 in | 0.004 in |

| ≥ 0.01 in | ≥0.006 in |

Etch Profile

Etch profile is maintained at approximately 10-20% of the material thickness.

Materials

Our most commonly used materials:

- Copper and Copper Alloys

- Stainless Steel: SS304, SS301, SS302, SS316, SS430

- Nickel & Nickel Alloys

- Mild Steels and Fe-Alloys