Stamping

Tanfel has been a provider of precision stamped metal parts and assemblies since 2008.

We provide stamped metal parts and product design assistance for your production or prototype needs. Our capacity ranges from 5 to 600 tons.

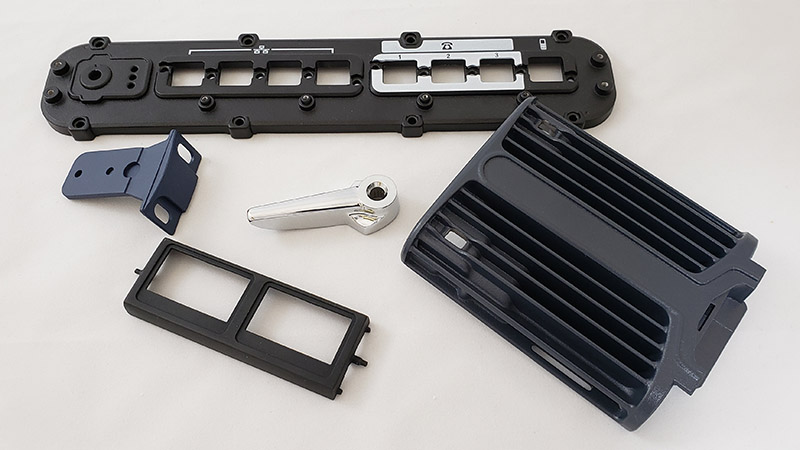

- Precision Metal Stamping

- Metal Stamping

- Deep Drawn Stamping

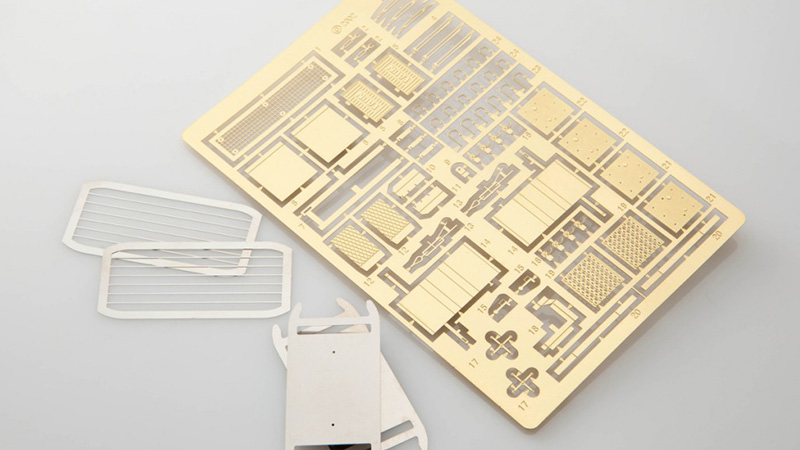

- Progressive Die Stamping

- Transfer Press Stamping

- Brazing and Welding

- Flat Forms and Wire Forms

- Turret punch

- Assembly

- Metal Finishing

- Tool and Die Design

- Piercing / Blanking

Learn more about the different metal stamping techniques.

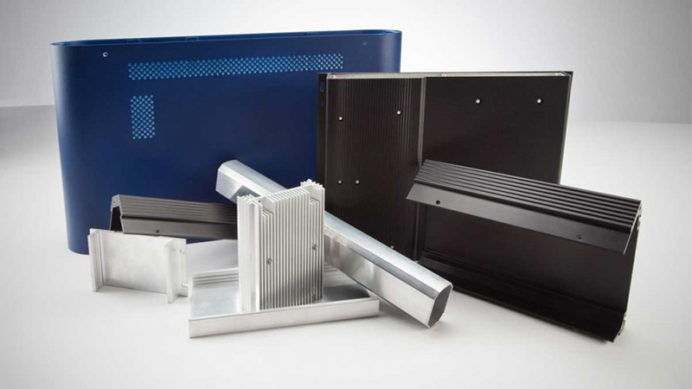

- Materials: Aluminum, Copper, Zinc, Steel, Nickel and Nickel Alloys

- 5 ton to 600 ton single and progressive die presses

- Progressive Die, Single die, Deep draw, Blanking / Piercing, turret punch, bending, laser cut

- Secondary operations: Drilling and tapping, CNC machining, grinding, EDM cutting, heat treating, stress relieving, welding, laser, argon and spot welding, riveting

- Finish: Anodizing, electroplating, powder coating, silkscreen and pad printing

- In house tool making

If you have any questions or would like to request a quote, contact us today.

| Category | Tolerance |

|---|---|

| Blanking & Piercing | ±0.0004 in |

| Forming | ±0.002 in |

| Deep Draw | ±0.002 in |

| Surface Roughness | Ra 0.8 |

| Straightness (CNC) | 0.0008 in |

| Tooling Manufacturing | ±0.0002 in |

| Flatness | 0.0002 in |

Max tool size capable: 135 in(L) X 40 in(W)

ISO 9001:2008

TS16949

ISO 13485

ISO 14001